-

Product DescriptionCompany Info.<>

- Processing customization:

- Yes

- Model:

- HL

- Treated gas volume:

- non-standard m3/h

- Purification rate:

- more than 90 %

- Specifications:

- non-standard

800KW/550KW oil associated gas generator set tail gas purification shale gas electric drive fracturing skid denitrationElectric fracturing skid is a special equipment used for shale oil and gas field development. It injects high-pressure liquid into rock formation through electric fracturing pump to form fractures and improve oil and gas permeability.

Characteristics and advantages of electric drive fracturing skid

performance parameter

Power: * High power 8000 hp, some models (such as Sany Heavy Industry SLQ100 5000) can reach 5500 hp, which is twice that of diesel drive equipment.

Weight and volume: The weight is only half of that of diesel drive equipment, the area is reduced by 50%, and continuous operation can be carried out without intermediate refueling.

Energy consumption and environmental protection: 30%-50% energy saving than diesel drive equipment, working noise reduced to 55dB (low noise model), suitable for continuous operation day and night without disturbing people.

cost-effective

Purchase cost: The price of a single electric fracturing skid is about 50% of that of diesel flooding equipment, but the comprehensive operation and maintenance cost can be reduced by 40%-60%.

Alternative plan: Model 8000 electric drive fracturing skid can replace 3 sets of Model 2500 oil drive fracturing trucks, reducing the number of equipment and management costs.

Application Scenarios and Significance

Application field: mainly used for shale oil development with complex geological conditions such as Subei Basin and Tarim Basin.

Industry significance: It marks that domestic shale oil exploration and development has entered a new stage of high efficiency and greening, and enhances the competitiveness of domestic equipment.

Hebei Hanlan introduced international advanced technology, independently developed SCR denitration system of internal combustion generator set, equipped with high-performance V-Ti or Fe-Zeolite catalyst, applicable temperature range is wide, life is long, and good purification rate can be maintained in the temperature range of 180-600℃. Through a series of key technology optimization, we greatly reduced the system resistance, improved the denitration efficiency, prolonged the catalyst life, and reduced ammonia slip. can realize ultra-low emission of nitrogen and oxygen compounds NOX and achieve the purpose of deep denitration.

Wanchun gas generator SCR denitration system also has the characteristics of safety and reliability, small back pressure, reasonable installation position, small occupied area, convenient maintenance and repair, etc., which greatly reduces the influence of denitration on internal combustion generator sets; at the same time, it selects urea injection system with good atomization effect, accurate injection angle, good material and corrosion resistance, and cooperates with advanced technology control system to accurately control urea consumption; PLC as the automatic control device of denitration system also has the characteristics of small size, convenient assembly and maintenance, high reliability and strong anti-interference ability, which not only facilitates remote centralized monitoring of pollutant emission data but also remotely controls the denitration system, greatly reducing the number and workload of system operation and maintenance personnel.

Performance index ofSCR flue gas denitrationsystem of Wanchun gas generator set

- § High efficiency, removal rate can reach more than 95%, can ensure the project nitrogen oxide removal effect;

- § catalyst activity temperature 300-580℃;

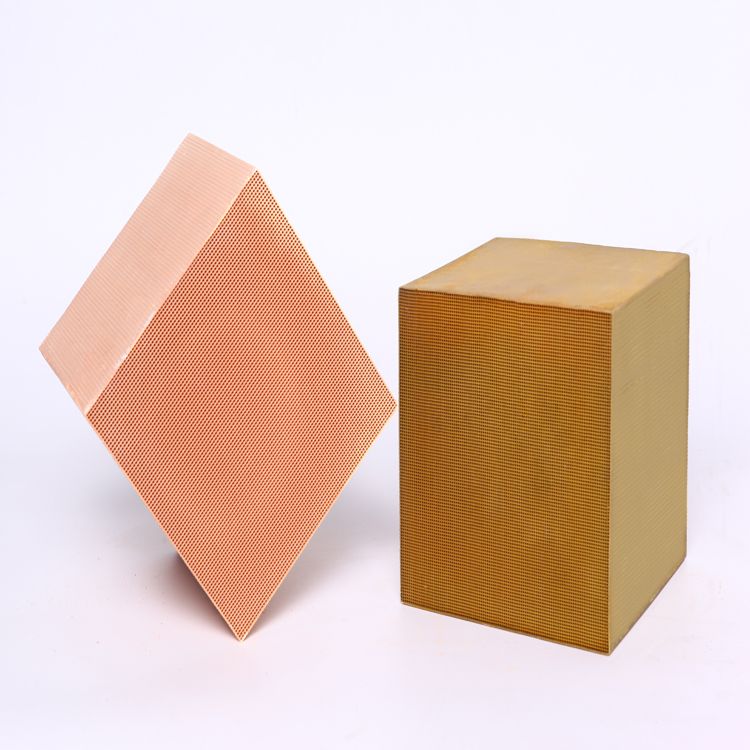

- § Honeycomb-shaped high-velocity catalyst with large specific surface area and compact volume;

- § Ammonia escape of flue gas denitration system shall be controlled below 2.5mg/Nm3;

- § The temperature loss of the whole equipment is less than 3℃, which meets the requirements of denitration and rear waste heat device.

- § The overall resistance of flue gas denitration system does not affect the normal exhaust of flue gas;

- § The denitration system has simple structure, no by-product, convenient operation, high reliability and relatively low one-time investment.

- § High degree of automation, good reliability;

- § The system combination is compact, simple and fast connection, strong corrosion resistance and excellent overall performance.

Our company can provide solutions according to the actual needs of customers, provide non-standard customized services, has undertaken thousands of projects, and many influential large enterprises at home and abroad such as Cummins, Caterpillar, and Veolia. Since our products are custom-made mechanical equipment, the pricing of equipment varies due to different product performance and parameters. The price of the platform is not for reference. If you are interested, please call or inquire online.

Company website: www.hanlantek.com, http://www.lanyu-tech.com, www.51scr.cn

Tel:

QQ:---- Name(chinese)

- Name(English)

- Hebei Hanlan Environmental Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Hebei, China

- Nearby port

- Qinhuangdao,Tangshan,Tianjin,Qingdao,Yantai

Hebei Hanlan Environmental Technology Co., Ltd. was founded in 2003, is a high-tech enterprise focusing on the field of power industry equipment, We specialise in the design, development and manufacture of exhaust gas purification equipment for generator sets, black smoke purifiers for diesel engines, exhaust gas purifiers for forklift trucks and high-performance high-pressure load banks. Among them, the exhaust gas purification equipment adopts advanced SCR denitrification technology, equipped with high-performance catalysts, realising ultra-low emission of NOx, with leading technology and high efficiency. The high-voltage load bank, with its precise power control, stable performance and strong environmental adaptability, has become the first choice for testing of generator sets and new energy devices. Hebei Hanlan Environmental Technology Co., Ltd. has successfully served many enterprises at home and abroad and won wide recognition in the market by virtue of excellent product performance, rich project experience and perfect after-sales service system. We are committed to providing customers with efficient and reliable environmental protection solutions, promoting green development and creating a better future.- Name(chinese)

- Name(English)

- Hebei Hanlan Environmental Technology Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Hebei, China

- Nearby port

- Qinhuangdao,Tangshan,Tianjin,Qingdao,Yantai

Hebei Hanlan Environmental Technology Co., Ltd. was founded in 2003, is a high-tech enterprise focusing on the field of power industry equipment, We specialise in the design, development and manufacture of exhaust gas purification equipment for generator sets, black smoke purifiers for diesel engines, exhaust gas purifiers for forklift trucks and high-performance high-pressure load banks. Among them, the exhaust gas purification equipment adopts advanced SCR denitrification technology, equipped with high-performance catalysts, realising ultra-low emission of NOx, with leading technology and high efficiency. The high-voltage load bank, with its precise power control, stable performance and strong environmental adaptability, has become the first choice for testing of generator sets and new energy devices. Hebei Hanlan Environmental Technology Co., Ltd. has successfully served many enterprises at home and abroad and won wide recognition in the market by virtue of excellent product performance, rich project experience and perfect after-sales service system. We are committed to providing customers with efficient and reliable environmental protection solutions, promoting green development and creating a better future. -

Send your message to this supplier*From:*To:

Ms. Grace.Zhang

*Message:

Ms. Grace.Zhang

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.